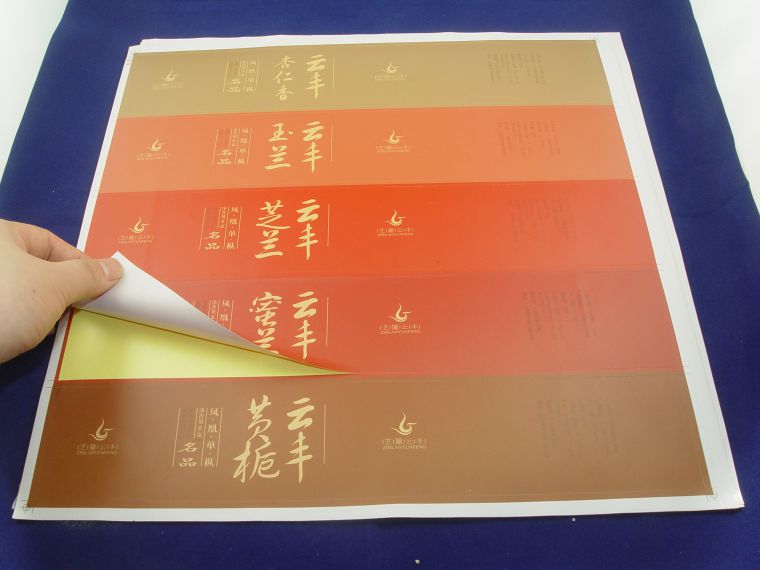

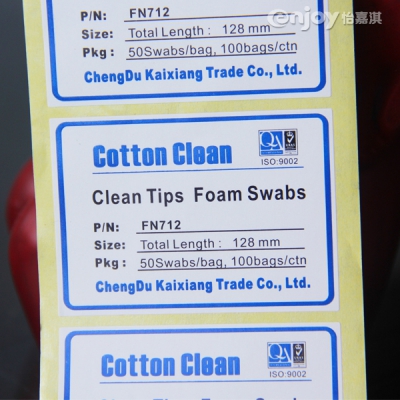

沐浴露(lu)标签加工选做:覆膜(亮膜,亚膜)、过油(you)(光油(you),亚油�����(you))、烫金(jin)(各种(zhong)颜色加激光)凹凸(tu)、局部UV、压纹等

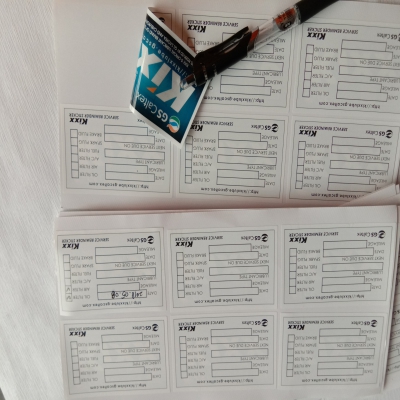

清(qing)洁剂标(biao)签标(biao)签胶水(shui):通(tong)用(yong)普(pu)粘(zhan)型,通(tong)用(yong)强(qiang)粘(zhan)型,特殊贴标(biao)要求可定做胶����水(shui)

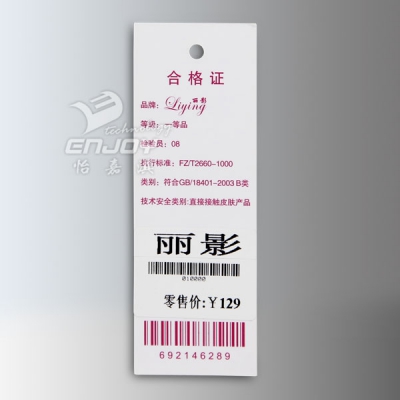

珠宝标签(qian)标签(qian)材料:NTC������格拉辛(xin)底铜(tong)版纸(zhi)(zhi)、NTC黄(huang)底铜(tong)版纸(zhi)(zhi)、艾利(li)进口铜(tong)版纸(zhi)(zhi)(均为格拉辛(xin)底),铜(tong) 版纸(zhi)(zhi),书写纸(zhi)(zhi) ,合成纸(zhi)(zhi),PET标签(qian)纸(zhi)(zhi)等

啤酒标签(qian)标签(qian)材(c�����������ai)料:PE、PP、PET薄膜(mo)类材(cai)质(zhi),特种(zhong)纸、BOPP薄膜(mo)、特殊不干(gan)胶纸等

牛(niu)皮纸标(biao)签(qian)标(biao)�������签(qian)特性:牛(niu)皮纸������不(bu)干胶标(biao)签(qian)质感出色(se),抗拉(la)力(li)强,耐磨,印刷清晰、颜(yan)色(se)深(shen)沉古典不(bu)褪色(se),厚(hou)薄均匀(yun),柔(rou)韧(ren)度好

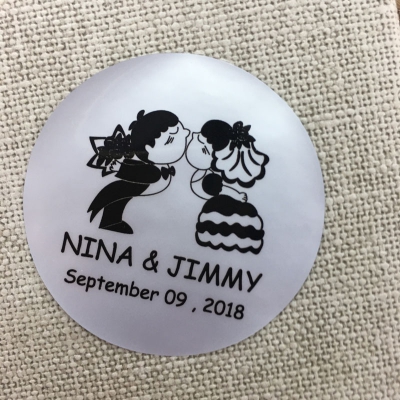

哑银PET������标签(qian)材质特性(xing):具有银色金属质感,防水防油,抗刮,耐高温,颜色鲜艳饱和等特点(dian)

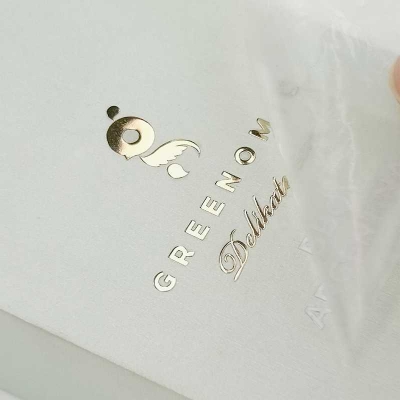

烫印(yin)温(wen)(wen)度对热熔性有机(ji)硅(gui)树(shu)脂脱落(luo)层(ceng)和胶粘剂的����(de)熔化程度有较大(da)影响,烫印(yin)温(wen)(wen)度一定不能(neng)低(di)于电化铝(lv)耐温(wen)(wen)范围的(de)下限(xian),这是保证电化铝(lv)粘胶层(ceng)熔化的(de)最低(di)温(wen)(wen)度。

柔(rou)性版(ban)(ban)(ban)(ban)(ban)印(yin)刷(shua)(shua)是一种(zhong)使用柔(rou)性版(ban)(ban)(ban)(ban)(ban)材、通过网纹辊传递油墨(mo)来实现印(yin)刷(shua)(shua)的(de)技(ji)术(shu)。与胶(jiao)版(ban)(ban)(ban)(ban)(ban)印(yin)刷(shua)(shua)、凹版(ban)(ban)(ban)(ban)(ban)印(yin)刷(shua)(shua)及凸版(ban)(ban)(ban)(ban)(ban)印(yin)刷(shua)(shua)等(deng)传统印(yin)刷(shua)(shua)技(ji)术(shu)相比(bi),柔(rou)性版(ban)(ban������)(ban)(ban������)(ban)印(yin)刷(shua)(shua)具(ju)有设备投资少、制版(ban)(ban)(ban)(ban)(ban)周期(qi)短、印(yin)刷(shua)(shua)速(su)度快、对(dui)承印(yin)物的(de)适应(ying)性强(qiang)、可使用环保型油墨(mo)等(deng)优点。

大(da)幅面彩色喷墨打印(yin)机的(de)打印(yin)头(tou)最容易因打印(yin)时间过长(zhang)、墨水使用不(bu)当(dang)、或长(zhang)时间搁置不(bu)用而堵塞喷孔。当(dang)然(ran)使用质(zhi)(zhi)��������量不(bu)佳的(de)墨盒(he),也会引起喷孔堵塞而影(ying)响打印(yin)������质(zhi)(zhi)量,严重时甚(shen)至导致整个打印(yin)头(tou)报废。

UV印刷是一(yi)种通(ton������g)过紫外光(guang)干燥、固(gu)化油墨的一(yi)种印刷工艺,需要含有光(guang)敏(min)剂的油墨与(yu)UV固(gu)化灯相配合,目(mu)前(qian)UV油墨已经涵(han)盖胶印、丝(si)网、喷(pen)墨、移印等(deng)领(ling)域。

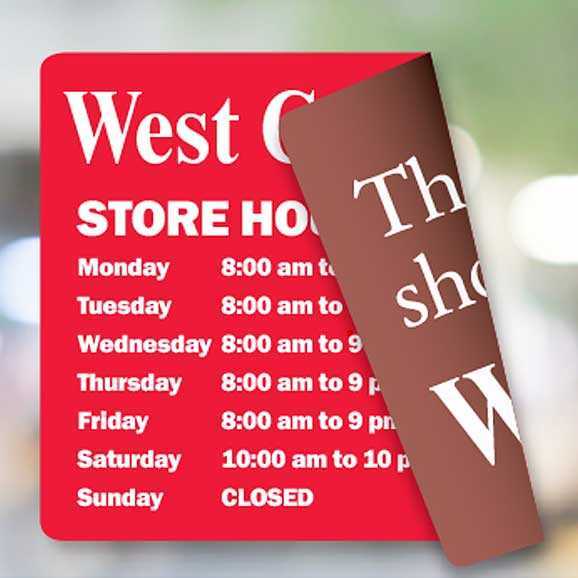

贴标(biao)(biao)机必(bi)须对标(biao)����(biao)站(zhan)的关注:刮(gua)(gua)胶(jiao)(jiao)板(ban)(ban)(ban)与(yu)(yu)胶(jiao)(jiao)辊(gun)(gun)的调(diao)整:刮(gua)(gua)胶(jiao)(jiao)板(ban)(ban)(ban)与(yu)(yu)胶(jiao)(jiao)辊(gun)(gun)在整个长度内不能出(chu)现(xian)间(jian)(jian)隙(xi),如(ru)果有间(jian)(jian)隙(xi)可(ke)(ke)以通过(guo)调(diao)整偏心螺栓(shuan)来调(diao)整刮(gua)(gua)胶(jiao)(jiao)板(ban)(ban)(ban)。胶(jiao)(jiao)辊(gun)(gun)与(yu)(yu)标(biao)(biao)板(ban)(ban)(ban)的调(diao)节:标(biao)(biao)板(ban)(ban)(ban)与(yu)(yu)胶(jiao)(jiao)辊(gun)(gun)之间(jian)(jian)只是(shi)相(xiang)互(hu)接触而没(mei)有任何(he)压力。间(jian)(jian)隙(xi)过(guo)大,标(biao)(biao)板(ban)(ban)(ban)上胶(jiao)(jiao)过(guo)多,造成甩胶(jiao)(jiao)。间(jian)(jian)隙(xi)过(guo)小,接触太(tai)紧,会(hui)将胶(jiao)(jiao)水挤(ji�������)走,标(biao)(biao)板(ban)(ban)(ban)半边没(mei)有胶(jiao)(jiao)水。实践证明(ming),标(biao)(biao)板(ban)(ban)(ban)与(yu)(yu)胶(jiao)(jiao)辊(gun)(gun)间(jian)(jian)隙(xi)在0.1mm~0.2mm之间(jian)(jian)为最(zui)佳。可(ke)(ke)以通过(guo)调(diao)整胶(jiao)(jiao)辊(gun)(gun)下部(bu)的轴(zhou)承(cheng)(cheng)座来实现(xian),必(bi)要时对胶(jiao)(jiao)辊(gun)(gun)上部(bu)的轴(zhou)承(cheng)(cheng)进行(xing)调(diao)节。

13691823896

13691823896