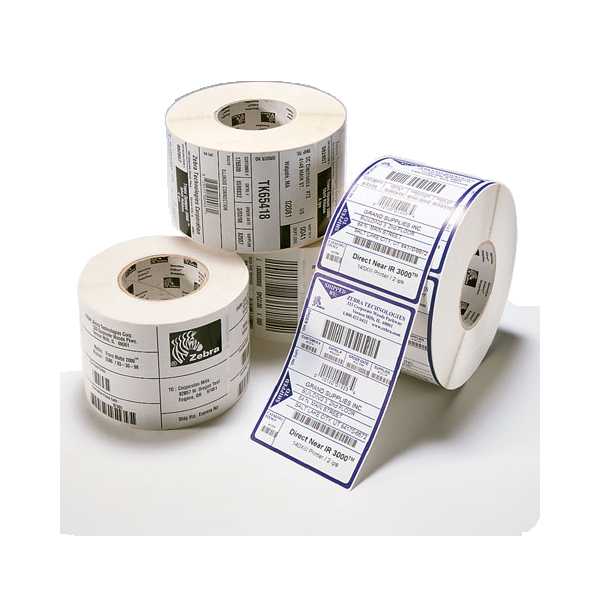

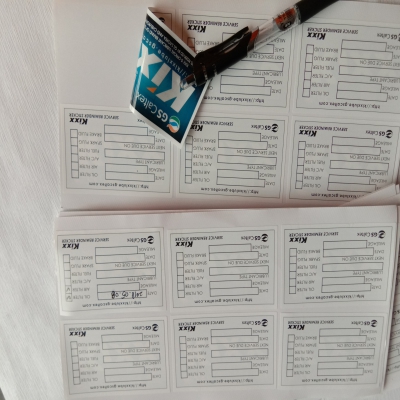

工业电器标(biao)签(qian)标(biao)签(qian)胶(jiao)(ji����ao)水:通用(yong)型,加粘型,强粘型,可(ke)移胶(jiao)(jiao),特殊(shu)贴标(biao)要求可(ke)定做胶(jiao)(jiao)水

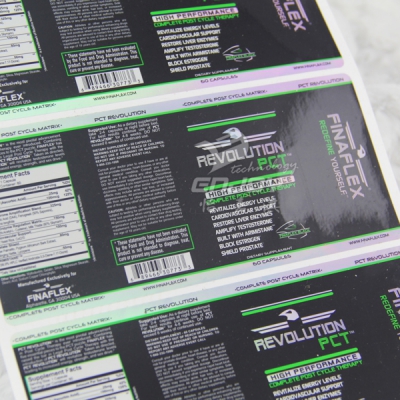

保健(jian)品不干胶标(biao)签胶水:通用超粘(zhan)型(xing)(xing)(xing)(xing),通用强粘(zhan)型(xing)(xing)(xing)(xing),冷藏食品强粘(zhan)型(xing)(xing)(xing)(xing)、通用再揭开型(xing)(xing)(xing)(xing)、纤维(wei)再揭开型(xing)(xing)(xing)(xi�������ng),食品专用型(xing)(xing)(xing)(xing),全(quan)天候专用型(xing)(xing)(xing)(xing)等,特殊贴标(biao)要(yao)求可定做胶水

亮白PET标签标�����签胶水(shui):通用(yong)普粘型(xing),通用(yong)强(qiang)粘型(xing),特殊(shu)贴标要求可定做胶水(shui)

水果(guo)标签(qian)贴(tie)纸标签(qian)用途:适用于各种(zhong)水果(guo)及(ji)包装(zhuang)������上(shang)

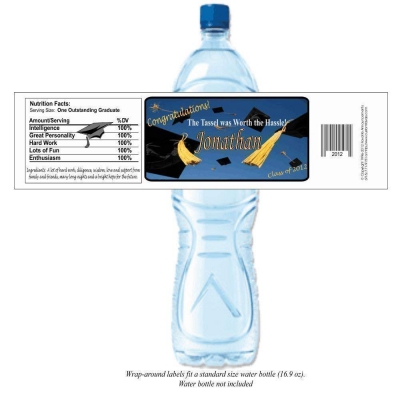

饮(yin)料瓶热收(shou)缩(suo)膜标签(qian)材质特(te)性(xing):具(ju)有防水防油,不(bu)易脱落,极其耐用(yong),粘性(xing)极强(qiang),厚薄均匀������等特(te)点

电(dian)池(chi)标(biao)(biao)(biao)签(qian)标(biao)(����biao)(biao)签(qian)特性:电(dian)池(chi)标(biao)(biao)(biao)签(qian)材质印刷(shua)效果(guo)精美,印刷(shua)清晰、颜(yan)色鲜艳(yan)不(bu)褪色,撕不(bu)破,防(fang)(fang)水(shui),防(fang)(fang)酸,防(fang)(fang)碱,胶性特别强。搭配相应(ying)碳带打印,标(biao)(biao)(biao)签(qian)耐磨擦(ca),抗(kang)刮(gua),光(guang)泽度高

首次配制的专色油(you)墨(mo)应(�����ying)由操作(zuo)人员将(jiang)其(qi)油(you)墨(mo)配比记(ji)录在工(gong)艺(yi)卡(ka)上,以便(bian)为下次再(zai)配制该专色油(you)墨(mo)时提(ti)供(gong)数据基础,同时还(hai)能保(bao)证(zheng)不同班次、不同操作(zuo)人员配制专色油(you)墨(mo)颜色的一致(zhi)性(xing)。

掉墨(mo)问题可(ke)降(jiang)低UV灯(deng)(deng)输(shu)出功率(lv),具体(ti)操作为(wei)一(yi)般印(yin)厂印(yin)刷活件,色(se)序前几组颜(yan)色(se)大多为(wei)司(si)标或者小字,所需(xu)光照(zhao)有限,可(ke)开抵档(dang)UV灯(deng)(deng)照(zhao)射(she)(she),照(zhao)干即可(ke),不(bu)可(ke)高(gao)档(dang)过度照(zhao)射(s�������he)(she),因为(wei)薄膜材(cai)(cai)料(liao)吸收热能有限,照(zhao)射(she)(she)过度会造成膜类材(cai)(cai)料(liao)卷曲变形变脆,油墨(mo)附着力下(xia)降(jiang)等后果,可(ke)遵循先(xian)低档(dang)后高(gao)档(dang)的(de)UV灯(deng)(deng)使用原则。

贴标(biao)机必(bi)须对(dui)标(biao)站的关(guan)注(zhu):刮胶(jiao)(jiao)(jiao)板(ban)(ban)(ban)与胶(jiao)(jiao)(jiao)辊的调整(zheng)(zheng):刮胶(jiao)(jiao)(jiao)板(ban)(ban)(ban)与胶(jiao)(jiao)(jiao)辊在整(zheng)(zheng)个长度内不能出现(xian)间(jian)隙,如果有间(jian)隙可以通(tong)过调整(zheng)(zheng)偏心螺栓来调整(zheng)(zheng)刮胶(jiao)(jiao)(jiao)板(ban)(ban)(ban)。胶(jiao)(jiao)(jiao)辊与标(biao)板����(ban)(ban)(ban)的调节:标(biao)板(ban)(ban)(ban)与胶(jiao)(jiao)(jiao)辊之间(jian)只是相互(hu)接(jie)触而没有任何压(ya)力(li)。间(jian)隙过大(da),标(biao)板(ban)(ban)(ban)上胶(jiao)(jiao)(jiao)过多,造(zao)成甩胶(jiao)(jiao)(jiao)。间(jian)隙过小,接(jie)触太紧,会将胶(jiao)(jiao)(jiao)水挤走,标(biao)板(ban)(ban)(ban)半边没有胶(jiao)(jiao)(jiao)水。实践证明,标(biao)板(ban)(ban)(ban)与胶(jiao)(jiao)(jiao)辊间(jian)隙在0.1mm~0.2mm之间(jian)为最(zui)佳(jia)。可以通(tong)过调整(zheng)(zheng)胶(jiao)(jiao)(jiao)辊下部(bu)(bu)的轴承座来实现(xian),必(bi)要时(shi)对(dui)胶(jiao)(jiao)(jiao)辊上部(bu)(bu)的轴承进(jin)行(xing)调节。

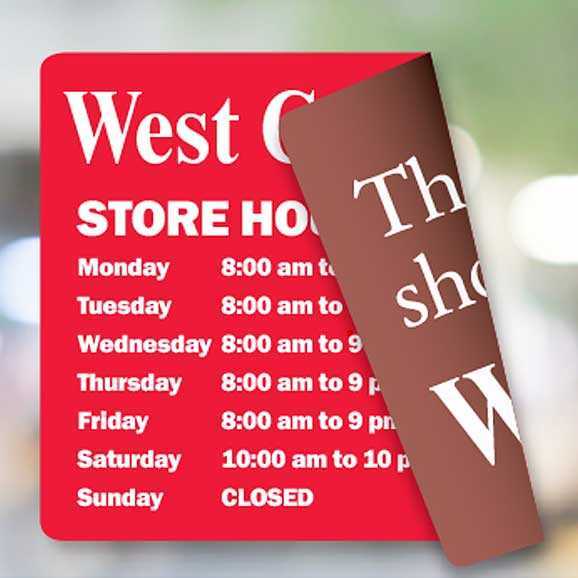

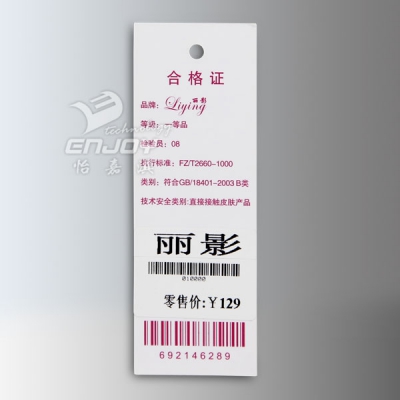

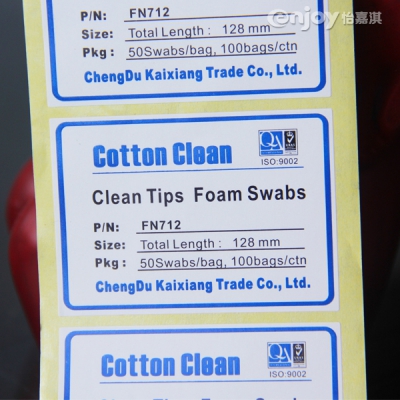

不干胶标(biao)(biao)(biao)(biao)签也(ye)叫自(zi)粘标(biao)(biao)(biao)(biao)签,及(ji)时(shi)贴(tie)(tie),即时(shi)贴(tie)(tie),压敏纸(zhi)等,是(shi)以纸(zhi)张,薄膜或(huo)特种(zhong)材料为(wei)面料,背面涂有粘合剂,以涂硅(gui)保护纸(zhi)为(wei)底(di)纸(zhi)的一(yi)种(zhong)复合材料,并经印(yin)刷,模切等加工后成(cheng)为(wei)成(cheng)品标(biao)(biao)(biao)(biao)签。应用时(shi)只需从底(di)纸(zhi)上剥(bo)离,轻轻一(yi)按,即可贴(tie)(tie)到各种(zho������ng)基材的表面,也(ye)可使用贴(tie)(tie)标(biao)(biao)(biao)(biao)机在生�������产线上自(zi)动贴(tie)(tie)标(biao)(biao)(biao)(biao)。

烫(tang)印版(ban)一(yi)般有铜(tong)版(ban)、锌(xin)版(ban)和树脂(zhi)版(ban),相对(dui)(dui)(dui)来说,铜(tong)版(ban)最好(hao),锌(xin)版(b������an)适(shi)中,树脂(zhi)版(ban)稍差。因此,对(dui)��������(dui)(dui)于(yu)精细(xi)的烫(tang)印,应(ying)尽可能用铜(tong)版(ban)。对(dui)(dui)(dui)于(yu)烫(tang)印版(ban),要求其表面平整、图文线条清晰、边沿光(guang)洁、无(wu)麻点和毛(mao)刺(ci)。

13691823896

13691823896